In the previous episode, I told the story of a software engineering team at Microsoft who used the Theory of Constraints to produce dramatic improvements in productivity.

But I hope something bothered you: how exactly did they know which changes to make? What process did they use to develop that particular set of solutions? Unless we know this, the best we can do is follow rigid prescriptions that are unlikely to work in different contexts.

Now we are finally reaching the very heart of TOC, the continuous improvement method used to increase throughput in any system of value creation, known as the Five Focusing Steps:

Step 1: Identify the constraint

This tells us where to focus our improvement efforts, since we know that only an improvement at the constraint (another term for “bottleneck”) makes a difference.

Step 2: Optimize the constraint

Before adding capacity, we need to use the capacity we already have. “Optimize” in this sense means “doing everything possible to use the constraint to its fullest capacity.”

Step 3: Subordinate the non-constraints

The job of all non-constraints is to “subordinate” themselves to the needs of the constraint, since that is what limits the throughput of the entire system.

Step 4: Elevate the constraint

Only once we’ve completed the previous steps does it make sense to add more capacity to the constraint, and thereby increase overall system performance. Because adding capacity is tremendously expensive, we do it as a last resort, not a first resort.

Step 5: Return to step 1

The inevitable result of the first four steps, and the reason this is a “continuous” improvement method, is that the constraint moves somewhere else. This step has you start back at the beginning.

Let’s take a closer look at Step #1, and why it represents a significant shift in how we normally conduct improvement within organizations.

Identifying the constraint

Because only improvements at the constraint make a difference to the company as a whole, identifying that constraint is the obvious first step.

The reassuring truth is that you don’t have to identify it perfectly from the very beginning. This is a self-correcting process, not a waterfall where small errors in the beginning become huge mistakes by the end. The advantage of working with a dynamic, interconnected system is that it responds very quickly to changes. The behavior of the system tells you whether you chose correctly.

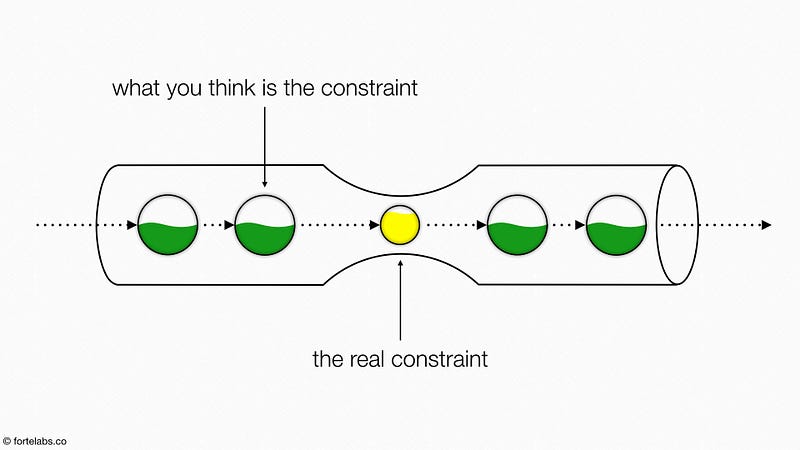

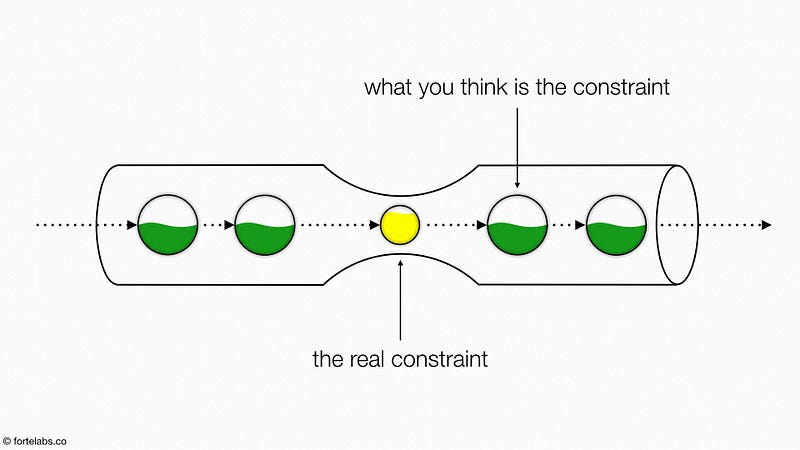

Let’s say you mis-identify the constraint, and add capacity there, but the real constraint is actually downstream:

Adding upstream capacity will only send more work to the real bottleneck, reducing its throughput and thus the system’s throughput. The irony of the situation is that system performance is deteriorating not despite your efforts to add capacity, but directly because of them:

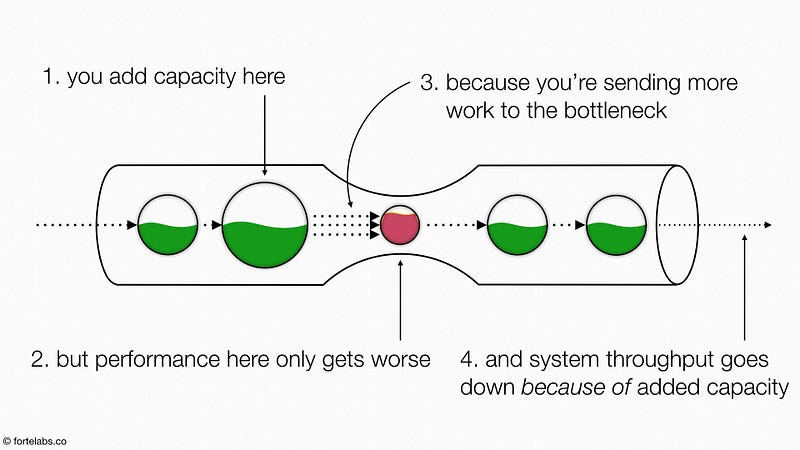

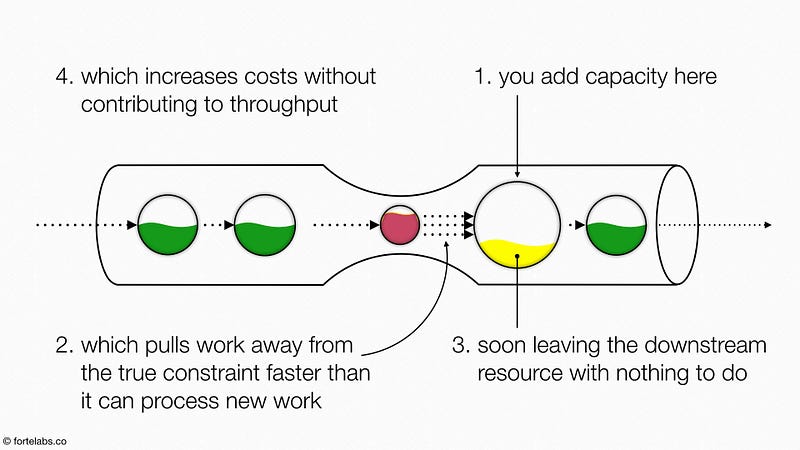

A similar thing happens when you mis-identify the constraint as being downstream of the true constraint:

Adding more downstream capacity pulls completed work away from the constraint more quickly than it can process new work. Which means this newly expanded department will soon be starved for anything to do, increasing costs while not contributing anything to throughput:

In this way, the behavior of the system tells you whether you’re improving the right thing. And it does it very quickly, in the form of changes to throughput that show up within days or weeks, instead of months or years.

What we’re talking about here is actually a fundamental change to how we go about improving any kind of complex system, such as a company.

Instead of collecting vast amounts of data on every aspect of the business, we acknowledge that we don’t have answers, only hypotheses. Instead of spending vast amounts of time making a detailed plan covering every contingency, we make our best guess as to where the constraint lies, and let feedback be our guide.

Instead of forcing all-encompassing rollouts changing every part of the company at once, we focus our attention intensely on one spot, even if we’re not sure it’s the right one. Instead of treating the constantly changing dynamics of the business as an enemy to contain, basing our decisions on point-in-time snapshots, we encourage the system to cycle even faster, so that our feedback loops will be accelerated.

We are trying to develop what the Germans call Fingerspitzengefühl, or “finger tips feeling” – an intuitive sense of the unfolding dynamics of a situation. As in sports or combat, you develop this instinct through high-frequency participation at the very center of action, not back in the office making plans.

To extend the metaphor, look at a map of the value stream of your organization. If you cannot put your finger on one spot that you believe might be the constraint, or aren’t willing to risk having this hypothesis proven wrong, you will never be able to focus your efforts. Without focus, you’ll be left starting dozens of random projects in random directions, hoping to hit on something through luck or by following prescriptions. Even if you do have a success, you won’t understand why.

This is why Goldratt said, if he had to summarize all of the Theory of Constraints in a single word, it would be focus.

Follow us for the latest updates and insights around productivity and Building a Second Brain on Twitter, Facebook, Instagram, LinkedIn, and YouTube. And if you're ready to start building your Second Brain, get the book and learn the proven method to organize your digital life and unlock your creative potential.

- POSTED IN: Flow